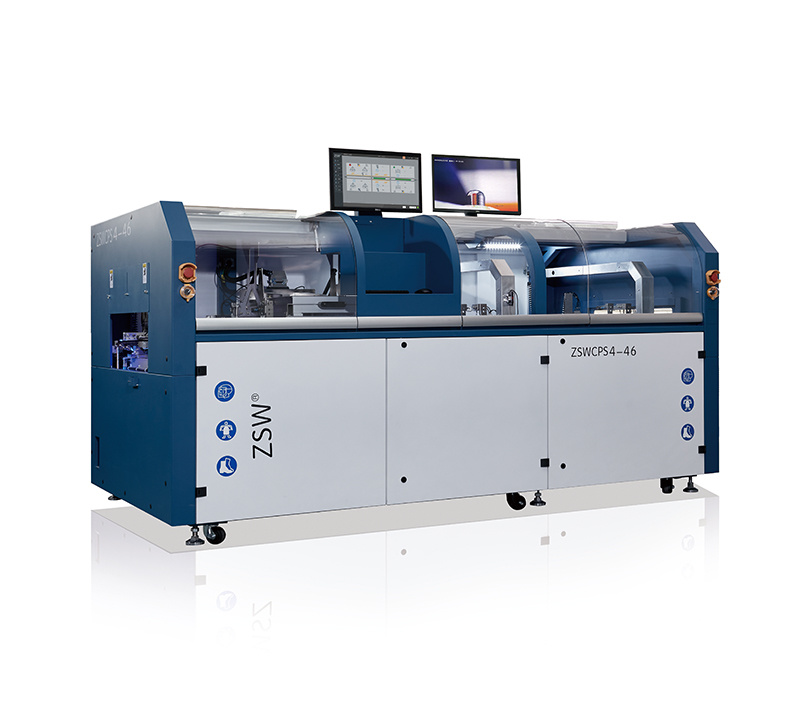

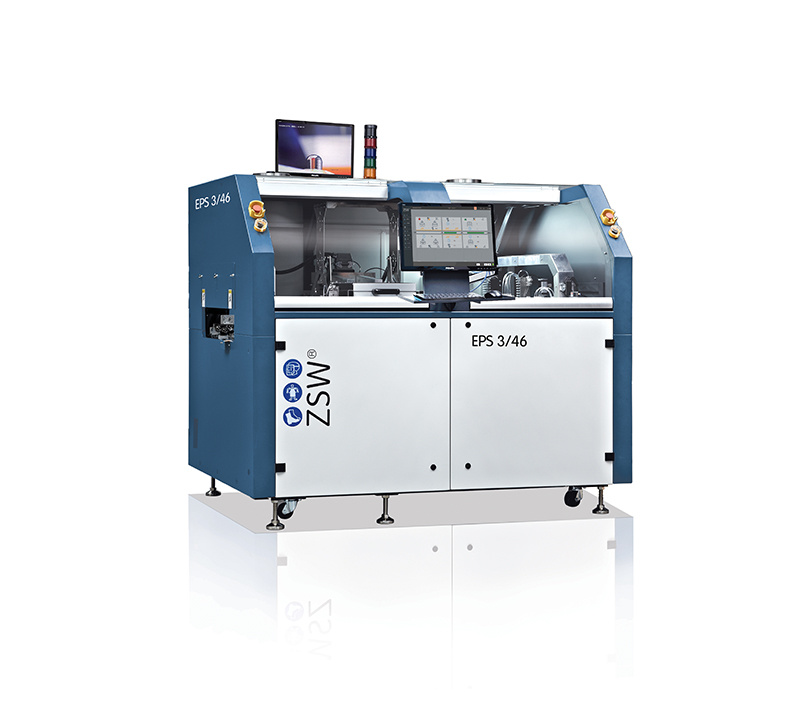

E Lead-free wave soldering series

Category:

Keyword:

Selective Wave Soldering | Wave Soldering

- Description

-

- Commodity name: E Lead-free wave soldering series

Specialised in high-end wave soldering for 15 years

Feature

1, selective spray, local nitrogen filling of tin furnace.

2. Compatible with customer MES system.

3. The plate feeding connection is designed to be horizontal, and there is no need for the board feeding machine.

4. The spray is kept away from the preheating area to eliminate fire hazards.

5. The preheated heating tube is a U-shaped high-temperature resistant stainless steel sintered pipe, with a service life of more than 12 years.

6. Modular design of preheating system, and good heat preservation measures.

7. 1/2HP high-power crest motor, the maximum peak height can reach 16mm. (20MM or more optional)

8. The amount of solder slag of the machine is low, 1KG/1OH.E I P WAVE SOLDERING SERIES TECHNICAL PARAMETERS COMPARISON TABLE

Form factor

4550x1625x

1715mm

4550x1885x

1715mm

4550x1885x

1715mm

PCB shipping direction

L--->R (R --->L 可选Optional)

Power supply (3-phase 5-wire) 3P5W380VAC,

50/60HZ 110A

3P5W380VAC,

50/60HZ 110A

3P5W380VAC, 50/60HZ 115A

Power supply power requirements

60KW

Air source power requirements

0.3- 0.7MPa

Total power

50KW

50KW 50KW

Normal operating power

12.5KW

12.5KW 12.5KW

Control mode

PC+PLC

Preheating method

Hot air/infrared/spotlight optional

Preheating fan speed regulation mode

Infinitely variable frequency speed regulation

Warm-up zone benefits

4

Length of warm-up zone

2300mm

Preheat temperature

Room temperature - 280 °C

Preheating and temperature control mode

PID+SSR mode

How the wave crest operates

Mechanical pumps

Tin furnace heat release tube power

1.0KW*12

Tin furnace capacity (Tin Bimi 7.5)

APPROX. 650KG

APPROX. 750KG APPROX. 820KG

The tin furnace limits the temperature withstand

MAX: 300°C

The limit operating temperature of the tin furnace

MAX: 280°C

Tin furnace control mode

PID+SSR building type

Wave peak drive power

1/2HPx23P 220VAC

1/2HP+1HP 3P 220VAC 1/2HPx1 1HPx1 3P 220VAC

Wave height adjustment method

Frequency conversion adjustment

Tin furnace heating time

150MIN set temperature 26°C

180M IN Set temperature 26°C

PCB transfer speed

0-1800mm/min

PCB board width range

80-350mm

80-510mm 80-610mm

PCB board component height

Top: 110mm Bottom: 25mm

PCB inlet shipping height

750±20mm

Transportation rail inclination

Standard 5.5° fixed, adjustable by about 50 norms

± 0.5°

Transport motor power

90W 3P 220VAC

Transport motor speed regulation mode

Frequency conversion speed regulation

Nitrogen consumption

15m3/ h100ppm or less

Nitrogen source pressure

0.5-0.8MPA

Oxygen content of nitrogen source

10PPM

Number of nitrogen flow meters

3

Exhaust pipe diameter

<P200mm

Online consultation

Email: huichun.xiao@zsw-ele.com

Add:No. 8, Huihao Industrial Park, Heshuikou Community, Guangming New District, Shenzhen

Website: http://www.zsw-ele.com

ZSW people adhere to the business philosophy of trustworthiness and ethics, with a persistent enterprising attitude, a rigorous and dedicated work style, a team spirit of concerted efforts, and always insist on ensuring that users are provided with high-end equipment and high-quality services that meet international quality standards and specifications. It has been recognized and favored by many well-known companies at home and abroad!

Copyright © 2023 Shenzhen ZSW Electronic Equipment Co., Ltd, All rights reserved.

Follow Us